Yuchen CNC cutting machine is widely used in the clothing industry, suitable for clothing cutting, proofing, edge-finding and cutting of printed fabrics, etc.

Yuchen's advanced software and hardware solutions have been helping the world's leading apparel brands and manufacturers maximize quality and profitability, and make their products faster, smarter, and better to market.

Advantage:

1. Smart material saving: Computer typesetting, saving more than 15% of materials compared with artificial intelligence

2. Automatic feeding: Automatic feeding, replacing 4-6 manual labor, supporting multi-layer feeding

3. Pattern patrolling and cutting: Intelligent extraction of contours of printed fabrics, edge inspection and cutting

4. High efficiency: 200-2500mm/s high-speed cutting, efficient replacement of multiple labor

5. No plate making required: Computer control, data import and cutting, simple operation, saving process

Cutting material:

Fabric Fabric

|

|

Suit |

|  Curtain Curtain

|

|  Clothes Clothes

|

Solution:

1. Cardboard input through SLR camera or digitizer input 1:1 output electronic version;

2. Automatic lofting system for carpets and sofa models, automatically adding or subtracting size, splicing, deleting, etc. according to customer requirements;

3. Model management, automatic typesetting, to achieve the highest cloth utilization rate, the layout speed is nearly 10 times that of manual, and the cloth length and utilization rate are clear at a glance;

4. The data is transmitted to the cutting machine, the equipment automatically places the cloth without manual leveling, and automatically cuts and locks the edges, which greatly improves the work efficiency.

Technical Parameters:

| Model:YC-1625L | Working area:2500×1600mm |

| cutting speed:1500mm/s | Cutting accuracy:±0.1mm |

| Transmission interface:Ethernet | Fixed mode:Vacuum absorb |

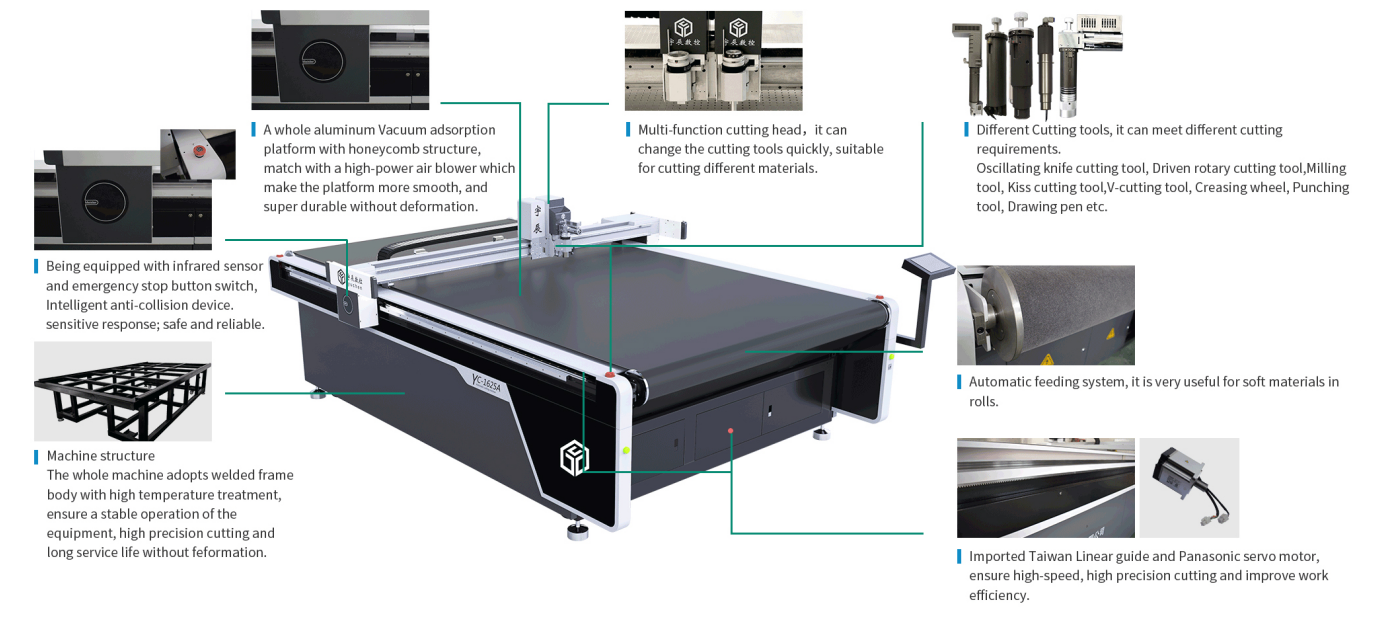

Machine details:

Cutting tool:

Driven Rotary Cutting Tool |

|  Oscillating Knife Cutting Tool |

|  Punching Tool |

Recommended machine: