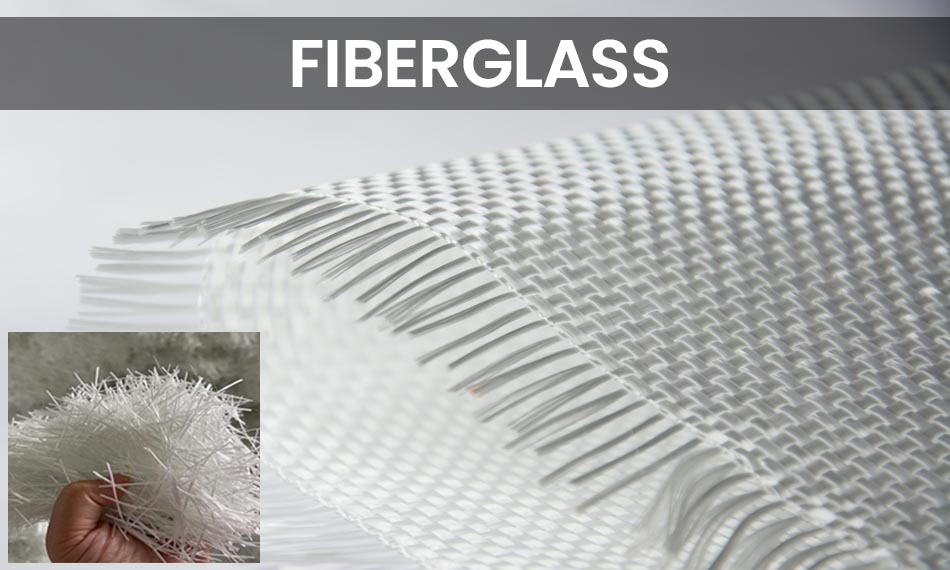

Fiberglass is a widely used composite material in industries such as automotive, marine, aerospace, and construction. Known for its durability, strength, and versatility, it’s a go-to choice for manufacturers worldwide. But while fiberglass offers excellent performance, cutting it can be a challenge. Traditional cutting methods often cause fraying, dust, and irregular edges.

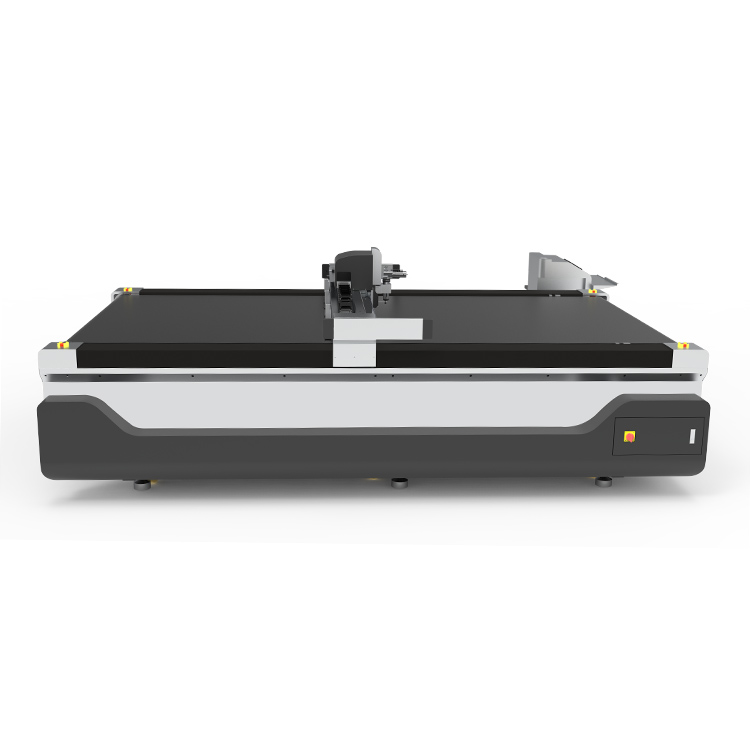

That’s where a fiberglass cutting machine—specifically, a CNC oscillating knife system from YUCHON—makes the difference. In this article, we’ll explore how vibrating knife technology simplifies fiberglass processing, delivers clean results, and boosts productivity across industries.

What Is Fiberglass and Why Is It Difficult to Cut?

Fiberglass is made by reinforcing plastic with glass fibers, typically in woven or chopped forms. It’s lightweight, corrosion-resistant, and highly durable, making it ideal for:

Boat hulls and parts

Automotive panels and dashboards

Industrial insulation and piping

Construction materials (e.g., wall panels, ducting)

Challenges in cutting fiberglass:

Produces fine dust harmful to lungs

Easily frays at the edges

Can chip or crack under high heat

Requires precision to prevent material waste

Why Choose a CNC Fiberglass Cutting Machine?

A CNC fiberglass cutting machine uses high-frequency vibrating blades instead of heat or friction to slice through fiberglass smoothly and efficiently. Unlike saws or lasers, it doesn't generate high temperatures, making it ideal for heat-sensitive composites.

Benefits include:

✅ Precision Cutting

✅ No Fraying or Burning

✅ Reduced Material Waste

✅ Low Dust Generation

✅ Time and Labor Savings

Key Features of YUCHON Fiberglass Cutting Machine

At YUCHON CNC, we design and build fiberglass cutting machines tailored for real industrial needs. Whether you’re working with glass fabric sheets, laminated composites, or hybrid panels, our solutions deliver.

Oscillating Knife System

High-frequency blade movement (up to 10,000 strokes/minute)

Adjustable depth to match different material thicknesses

Smart CNC Control

Camera-Based Alignment (Optional)

Vacuum Adsorption Table

Real-Life Application: Fiberglass in Automotive Interiors

One of our automotive partners recently switched from manual cutting to a YUCHON fiberglass cutting machine for dashboard insulation panels. Results included:

35% faster production time

20% savings on material waste

Consistent edge quality on every cut

Explore more use cases for composites.

How to Get Started with YUCHON

We offer customized cutting solutions based on your production scale, material types, and automation needs. Our team provides:

Visit our product page to request a quote or schedule a live demo.

Conclusion

Cutting fiberglass doesn’t have to be difficult. With a CNC fiberglass cutting machine from YUCHON, manufacturers can enjoy clean, accurate cuts, reduced waste, and safer operations. Whether you’re in automotive, marine, or industrial manufacturing, our technology helps you stay ahead of the curve.